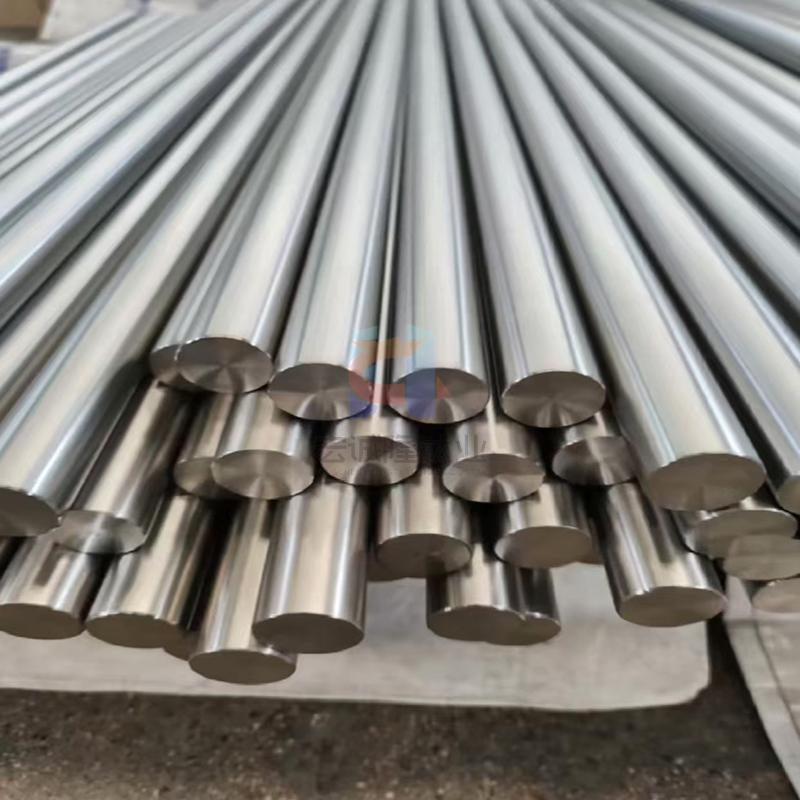

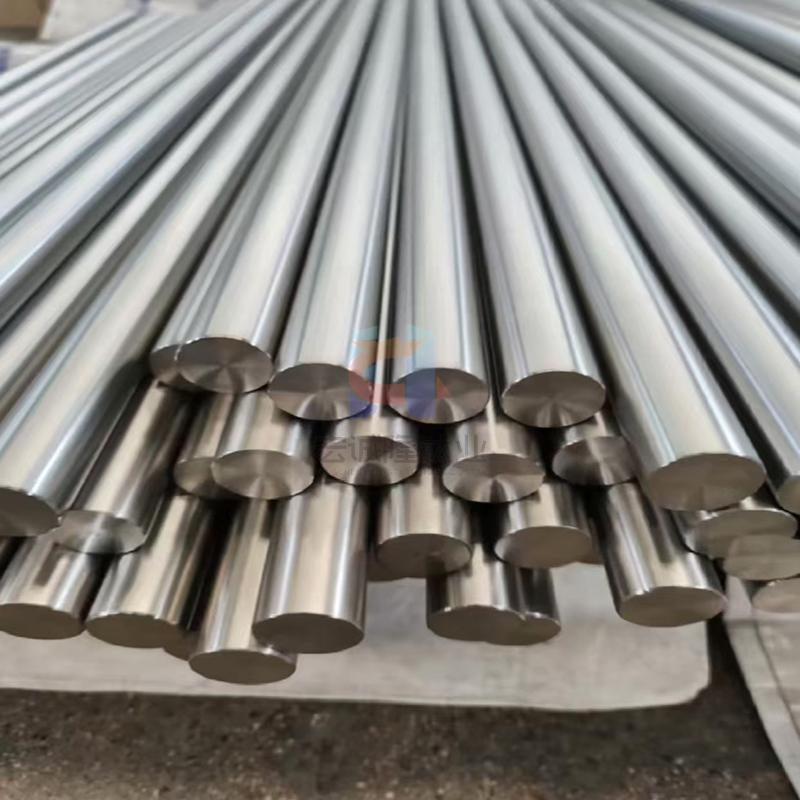

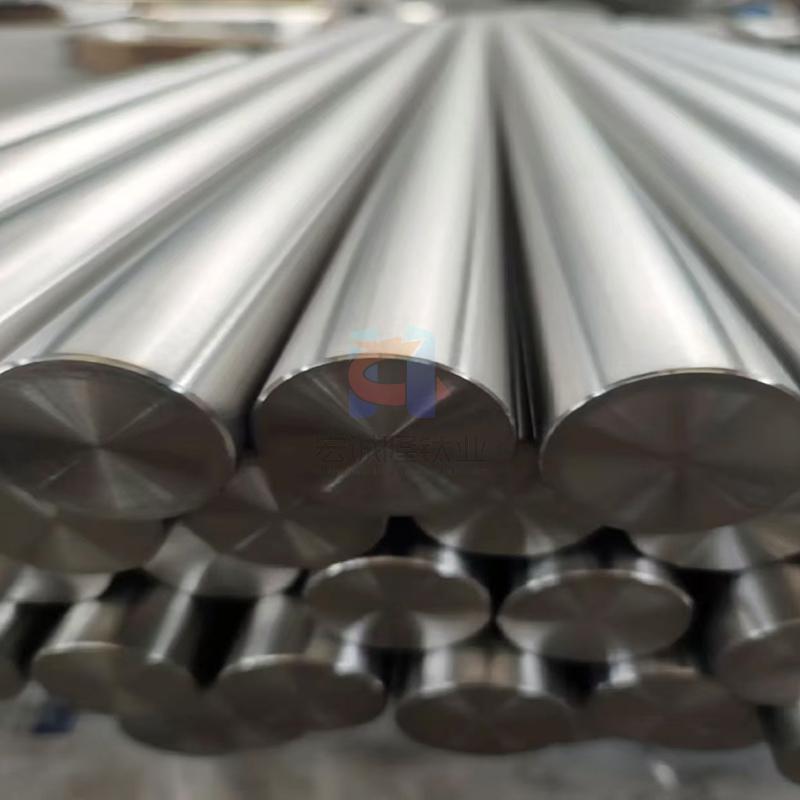

Overview of Titanium Rod

Blunt titanium rod and titanium alloy rod are new structural materials, which are characterized by high melting point, low specific gravity, high specific strength, good toughness, fatigue resistance, acid and alkali corrosion resistance, low thermal conductivity, good high and low temperature tolerance, and low stress under rapid cooling and heating conditions. Applied in high-tech fields such as aviation and aerospace, and continuously promoted to industries such as chemical, petroleum, power, seawater desalination, construction, and daily necessities.

Shape: Round rod, square rod, hexagonal rod, irregular rod.

Common grades of titanium rods

National standard grades: TA1, TA2, TA3, TA7, TA9, TA10, TA15, TA18, TC4, TC4ELI, TC6, TC9, TC10, TC11

American standard grades: GR1, GR2, GR3, GR4, GR5, GR7, GR11, GR12, GR23, etc.

Titanium rod manufacturing process

Hot forging hot rolling annealing straightening turning (polishing) polishing flat head inspection packaging

Titanium rods comply with commonly used standards

National standards: GB/2965-2007, GB/T13810

American standards: ASTM B348, ASTM F136, ASTM F67, AMS4928

Titanium rod supply status: hot processing status, annealing status

Hot rolling: a rolling process carried out at temperatures higher than the recrystallization temperature.

Cold rolling: a rolling process in which the plastic deformation temperature is lower than the recovery temperature.

Annealing: A metal heat treatment process in which a metal is slowly heated to a certain temperature, held for a sufficient period of time, and then cooled at an appropriate rate (usually slow cooling, sometimes controlled cooling).

Acid washing: Immerse the workpiece in an aqueous solution such as sulfuric acid to remove thin films of oxides and other substances on the metal surface. It is a pre-treatment or intermediate treatment for electroplating, enamel, rolling and other processes.

Characteristics of titanium plate:

1. Titanium plate is a surface oxide film that acts as a good durable and wear-resistant separating agent. Using titanium plate saves the separating agent, making it easy to peel off the electrode plate and eliminating the need for pre-treatment. Titanium plate is half lighter than copper plate.

The service life of titanium plate is more than three times that of copper plate, and can reach 10-20 years according to operating conditions.

3. Electrolytic copper produced from titanium plates has a dense crystal structure, smooth surface, and excellent quality.

4. Due to the fact that titanium plates do not require the application of separation agents, contamination of copper electrolyte can be avoided.

5. Improve production capacity and reduce the production cost of electrolytic copper, thereby achieving better economic benefits.